CRYOTRUCKS® - ECOLOGICAL AND ECONOMICAL

CRYO-KIT

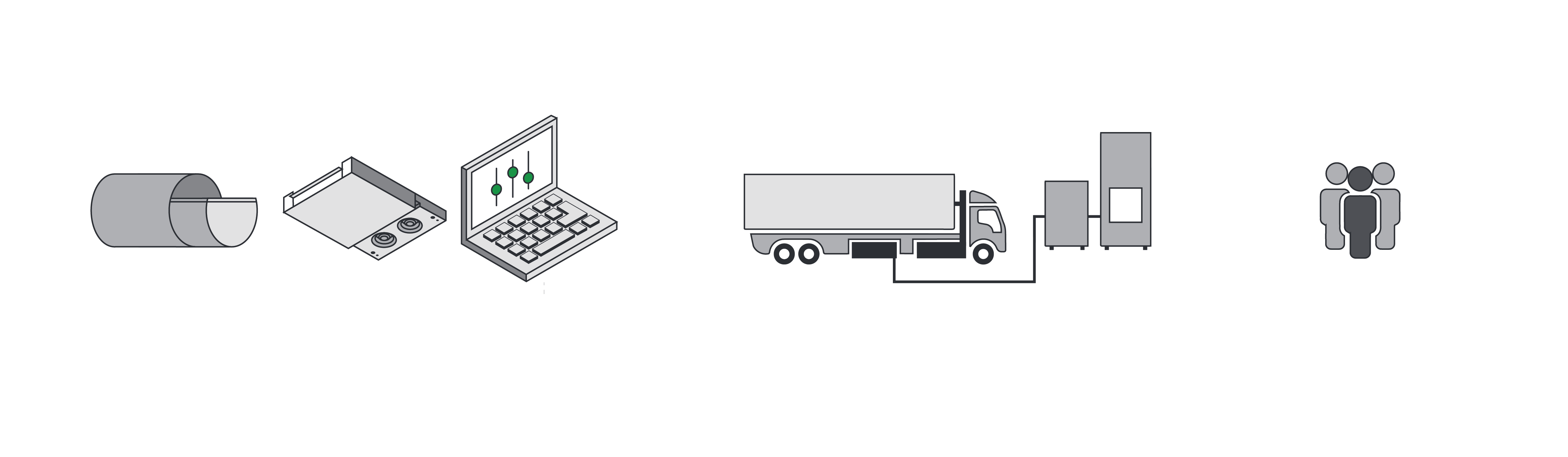

The CRYO-KIT by CRYOTRUCKS® consists of 3 components: the tank, the controller and the vaporizer. This has already been homologated and approved in accordance with the latest 2022 EU directives and can be installed in any new refrigerated trailer or as a replacement system for an obsolete diesel system.

Through cryo technology, we use the cooling potential of liquid nitrogen as a substitute for diesel-powered systems. After the liquid nitrogen has released its cooling energy, it gets released back into the atmosphere, where it is contained at 78%. Since the system does not use engines, it has a noise level of less than 45 db, which allows it to be used at night in urban areas.

Cryogenic technology is indisputably an innovative and clean solution to avoid diesel emissions in the transport sector. Hence, as a result, the emissions are reduced practically to zero. The nitrogen alternative also brings considerable advantages from an economic point of view, as the maintenance and service costs are significantly lower compared to conventional cooling systems based on diesel units. In addition, as shown by field reports, food refrigerates in a more gradual and effective way.

Our Cryo-KIT is far more powerful and efficient than conventional cooling systems:

The nitrogen cooling system was developed by NASA researchers back in 2005 and has already been in use on Europe's roads for 7 years, thus, already proving its functionality. However, the system has been further developed by CRYOTRUCKS® and is offered by us, primarily as a new kit, which also makes it possible to retrofit outdated systems.

Truck cooling function

1 Nitrogen container

2 evaporator

3 Cooling

4 Heat output

Advantages

- Saving of

environmentally harmful exhaust gases - Reduction of greenhouse gases

and thus maintain the balance of the ecological equilibrium - High economic efficiency; little maintenance necessary

- Low noise emission, allowing use in urban areas even at times when it would otherwise be prohibited

- Significantly reduced weight due to the aluminium tank and thus higher economy and loading capacity

- Fast and uniform cooling over the entire length of the load compartment

- Faster reaching of the operating temperature

(-1° per minute) - Higher efficiency in

maintaining the cold chain - Service life of the system

over 10 years